The counter in the control room of ASDEX Upgrade has stood at 41,570 plasma discharges since 27 July 2022 – and that will not change for two years. The 41,570th discharge was the last before the major reconstruction of the tokamak in Garching. ASDEX Upgrade is now being prepared for its next mission: testing a new divertor concept in which the magnetic flux tubes are flared near the power-receiving wall sections, i.e. close to the divertor. For this purpose, the following main components have to be installed:

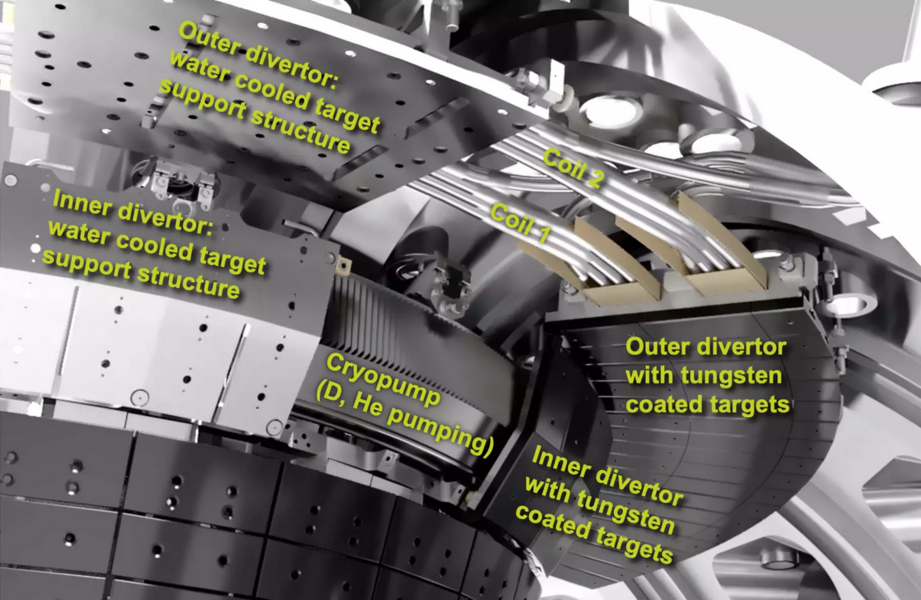

- cryopumps,

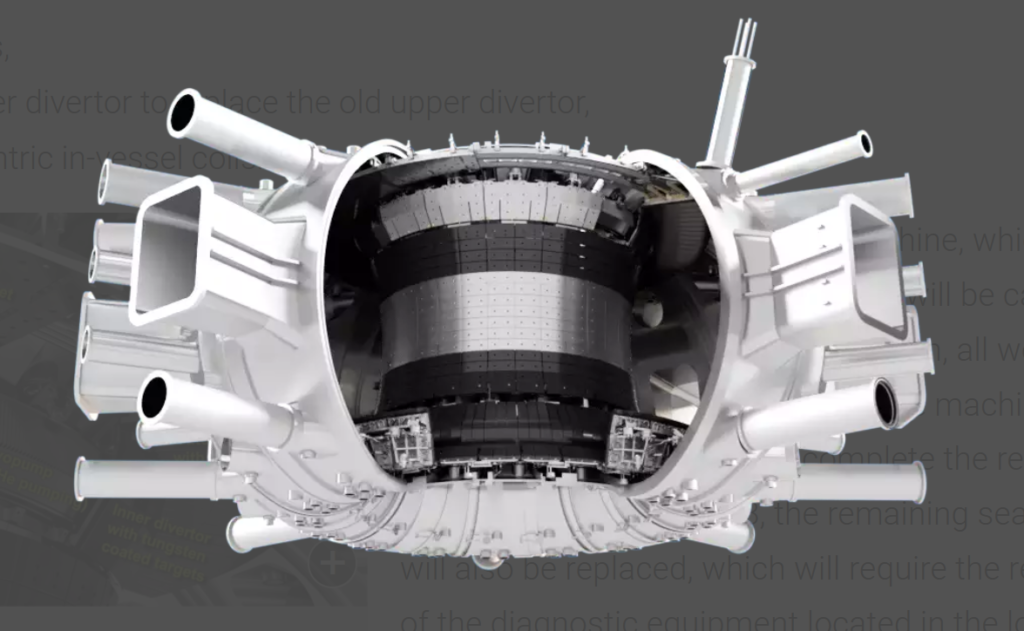

- a new upper divertor to replace the old upper divertor,

- two concentric in-vessel coils.

To ensure the operation of the machine, which is more than 30 years old, a thorough inspection will be carried out to check its current condition. In addition, all wear-prone components required to maintain the machine’s ultra-high vacuum will be replaced. To complete the repair work caused by water damage in 2018, the remaining seals (Helicoflex) will also be replaced, which will require the removal of much of the diagnostic equipment located in the lower ports of the vessel.

The Ausbau team led by Irene Zammuto has been preparing intensively for this mammoth task for two years. Using a full-size model of ASDEX Upgrade, the team rehearses all the steps involved in assembling the upper divertor. The new divertor is equipped with high-precision tungsten-coated graphite plates. The core elements of the upper divertor are the two concentric magnetic coils (with four turns each), through which the magnetic field is expanded. Due to the technological choice of the conductor and the geometry of the coils, the coils have to be bent inside the vacuum vessel. This requires a special 700-kilogram bending machine, which on the one hand is small enough to be brought into the vessel on rails. On the other hand, it must have enough power to form the more than thumb-thick copper conductors with stainless steel sheathing (18 millimetre copper diameter plus 2.5 millimetre insulation layer and 1.5 millimetre stainless steel) into four coils with a maximum diameter of 3.1 metres.

The project plan lists 910 work steps. For each of them, the time allotted is noted down to the tenth of a working day. It divides the work inside the vacuum vessel into six phases. In parallel, modifications take place outside the vessel. “According to what more experienced colleagues have told me, we are working with the most detailed project plan ever drawn up at IPP Garching,” says Irene Zammuto. If everything goes according to this plan, ASDEX Upgrade will resume experimental operation in July 2024, after 514 working days and nine milestones achieved.

However, Irene Zammuto points to imponderables that could force the team to change the plan. These include:

- The course of the coronavirus pandemic.

- The bending of the coils will not be tested on the model until March 2023.

- The removal team could encounter previously undetected damage after opening the vacuum vessel, which would lead to longer repair times.

The team will check progress weekly. An updated version of the project plan can be expected every two to three months.