Wendelstein 7-X has been operating in Greifswald since December 2015 and is being commissioned in stages. Whereas in the first two experimental phases the plasma was initially confined using a magnetic field cage and an uncooled exhaust (divertor), a water cooling system has just been installed. This should make possible half-hour-long plasma discharges at high heating power in Wendelstein 7-X.

The first three experimental phases of Wendelstein 7-X were highly successful: Among other things, the team was already able to set the stellarator world record for the so-called triple product of temperature, density and confinement time. This triple product is a measure of the performance of fusion experiments.

However, Wendelstein 7-X is not yet complete and is undergoing upgrades in 2021. When the stellarator started up in December 2015, the plasma was confined using a so-called limiter configuration. This already allowed for good studies with the facility, but only for the short time of about one second. In 2017/18, the team switched to the divertor configuration magnetically limited the hot plasma, through a so-called divertor. This allows the interaction of the hot plasma with the material walls to take place separately and far away from the magnetically confined plasma interior.

Divertors were first used successfully in the early 1980s at the ASDEX tokamak at the Max Planck Institute for Plasma Physics in Garching and are now standard in all fusion facilities. Unlike tokamaks, whose divertor is axially symmetric, in stellarators it is asymmetric and therefore three-dimensional. Wendelstein 7-X features ten separate divertor modules, one at the bottom and one at the top of each of the five sectors that make up the facility.

The divertor used in the second experimental phase was covered with carbon plates. It did not yet have active cooling, which limited the plasma duration to a few tens of seconds. Between plasma discharges, the plates cooled down again by emitting heat and light. Because of this intrinsic limit, steady-state plasmas were not possible. During this phase, Wendelstein 7-X carried out fundamental studies and investigated many important physical aspects – but this was only an intermediate step.

Towards continuous operation

A major advantage of the stellarator is that it can in principle run in continuous operation, whereas tokamak-type facilities operate in pulsed mode. An important mission of Wendelstein 7-X is to prove this advantage and demonstrate 30-minute long plasma discharges at high heating power. To reach this goal, the power supplied to the plasma also has to be dissipated in a stationary manner. This is only possible with water cooling of the divertor and other parts of the plasma vessel.

Upgrade campaign

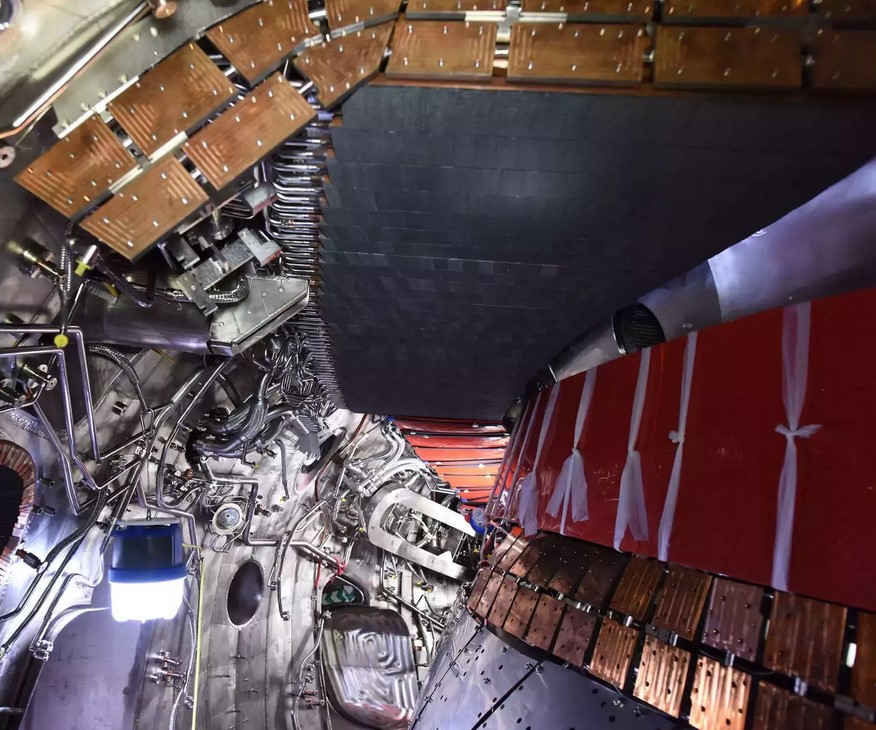

Upgrades since 2019 have equipped Wendelstein 7-X with the active water cooling necessary for steady-state operation. The old divertor has already been completely removed and has just been replaced by an actively cooled one. On the side facing the plasma, it has the same contour as the uncooled divertor, but now consists of carbon fiber-reinforced carbon tiles (CFC) welded onto water-cooled metal plates.

The total of 120 divertor tiles required were designed, built and tested over the past several years at the Garching branch of the Max Planck Institute for Plasma Physics. Since the individual divertor modules weigh up to 70 kilograms but have to be installed with a tolerance of less than one millimeter, assembly is very time-consuming. In addition, security measures during the Corona pandemic complicated the work and required more time than anticipated.

As part of the work, around seven kilometers of water pipes were laid in the plasma vessel, which had to be bolted or welded at around 3000 separation points. Because of the confined space in the plasma vessel, this was also a very time-consuming and complex job: All seams had to be tight, and neither air nor water leaks were allowed!

Ten cryovacuum pumps are installed in the extremely confined space behind the divertor, cooled with water, liquid nitrogen and liquid helium. The five upper cryogenic pumps have already been installed and tested for leaks. The divertor modules have also been successfully installed in the upper part of the plasma vessel, so that assembly of the lower divertor modules can now begin.

The divertor is supplied with cooling via 480 water circuits, which also require extensive installations outside the plasma vessel. Here, too, installation space is at a premium. In addition, numerous other plant components are being modified or rebuilt during this expansion phase, including cryopump cooling, another high-frequency heater, stronger transmitter tubes for electron cyclotron resonance heating, and many plasma diagnostics – a complex mix of different jobs that were affected to varying degrees by the Corona pandemic.

Restart in 2021

Assembly of all is now scheduled for completion by the end of 2021, about six months later than originally planned. In parallel, preparations are already underway for the commissioning of Wendelstein 7-X after the modification. The water cooling of the divertor – a completely new chapter for the operation – is being prepared, as well as the operating and safety controls and the sequence of experiments, so that we can probably start researching plasmas in Wendelstein 7-X again in the summer of 2022.