When you think of an artificial star, immense heat certainly comes to mind. Inside an experimental fusion device like ITER is a seething cloud of hot, charged hydrogen gas (a plasma) of 150 million degrees Celsius. Even with cooling, the inner walls of the vacuum chamber reach over a thousand degrees Celsius. But heat isn’t the only challenge for the engineers designing future fusion power plants. Hydrogen fusion produces helium, a lot of energy, and ultra-fast subatomic neutron particles that can damage nearby materials.

Billions and billions of neutrons

Any material used to construct ITER had better be ready for a torrent of fast neutrons. At full power, fusion reactions in the tokamak are expected to send up to 10^14 (hundreds of thousands of billions) neutrons at every square centimetre of the device’s walls – every second. Those impacts can cause all kinds of changes in the material compared to the original state.

Over their full lifetime, each atom in the structural steel components will be hit by a neutron and jostled from its original position at least three times in an ITER Test Blanket Module. And it will happen fifty or more times in a future commercial fusion power plant. Inevitably, this can change the materials’ properties, such as reduction of strength and toughness, development of micro cracks or even rupture.

Lifetime tests

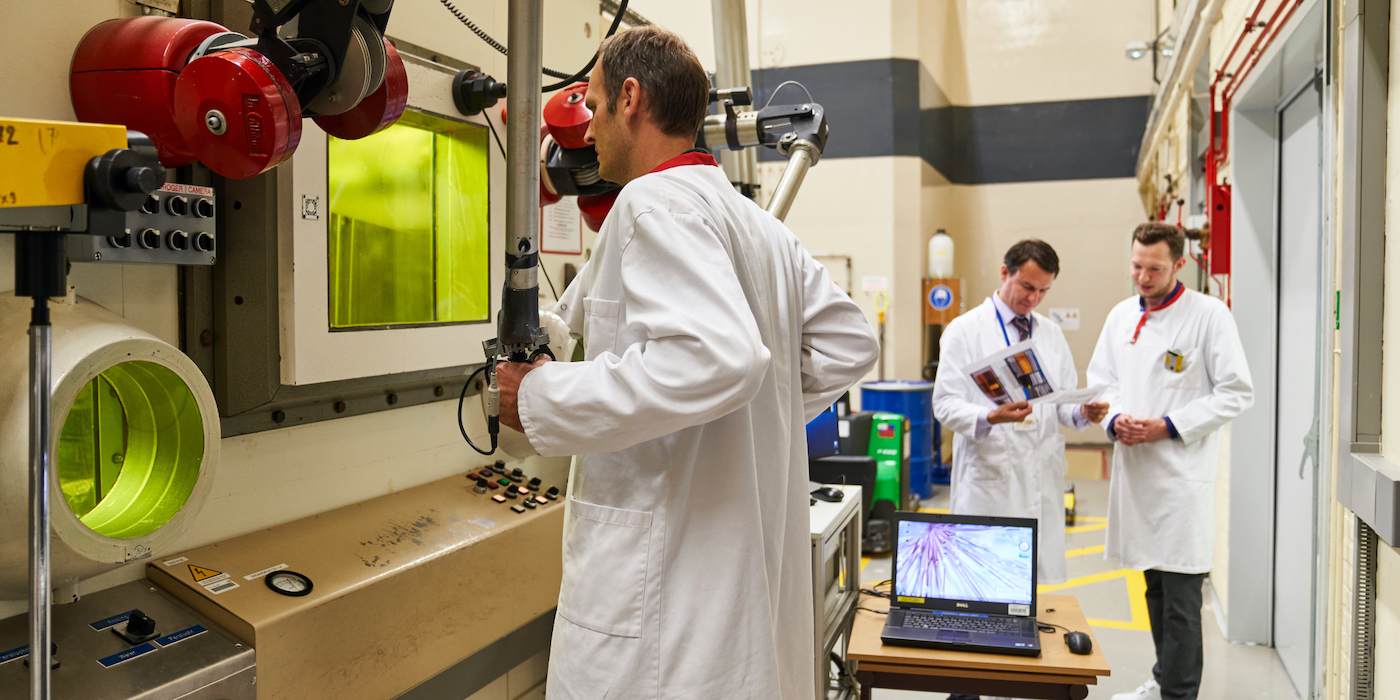

To investigate exactly how ITER’s structural materials will hold up over their multi-year lifetime, EUROfusion together with F4E have contacted the Belgian nuclear research lab SCK CEN in Mol. It wasn’t the first time that nuclear physicist Dr Dmitry Terentyev and his team had performed research for ITER: over the last decades, Terentyev and his team have investigated diagnostic components like coils, mirrors and lenses, as well as functional and protective materials. Their first neutron irradiation experiment for fusion dates back to 1987.

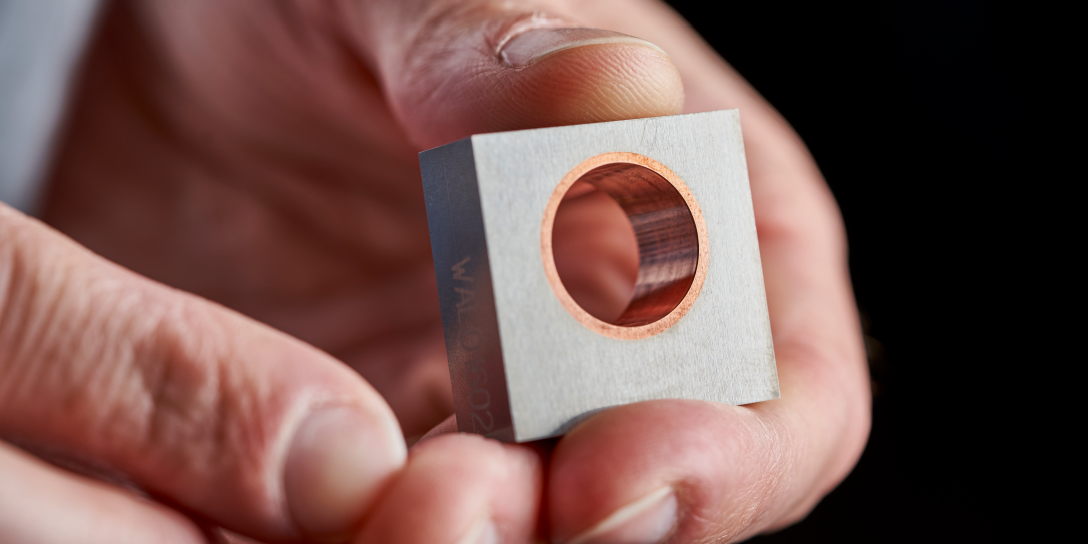

Terentyev’s team embarked on a two-year experiment to see how well various materials would fare under ITER-like conditions. The team investigated tungsten, which protects the divertor where the helium leaves the ITER central chamber, copper for cooling channels and steel that supports the 30–meter-high and -wide device. “These are materials for ‘first wall’ components”, explains Terentyev. “They will be in direct contact with the hot plasma in ITER and without shielding from the fast neutrons.”

While SCK CEN doesn’t have its own fusion device, the research centre does feature the fission research reactor BR2, which produces large amounts of neutrons. Inside BR2, the material samples spent two years facing a temperature of up to 1200 degrees Celsius in a hail of neutrons from uranium fission. “This was the most intense materials test we ever performed in the history of BR2”, says the physicist.

Dedicated facilities

While the BR2 reactor can produce a flux (impacts per surface area per second) of fast neutrons similar to that in ITER, the neutrons’ energy is different. “The fusion reaction in ITER will produce neutrons with an energy of 14.1 MeV (million electronvolts, a standard unit in particle physics – ed.)”, explains Terentyev, “while ‘fission neutrons’ come in at around 2 MeV on average.” Neutron absorbers in BR2 weed out especially slow ones, but neutron conditions in a fission and a fusion reactor are still not identical. That is why dedicated fusion irradiation facilities are now being developed, such as IFMIF-DONES in Spain and the particle accelerator and reactor MYRRHA in Mol, Belgium.

Results

SCK CEN will now partner with other EU research labs to investigate how the high speed neutrons have impacted the thermo-mechanical properties of the irradiated samples. The first results are already published in specialised journals and disseminated at the latest conferences held in 2020, like NUMAT and SOFT. The intensive post-irradiation studies are to be completed by 2022 to provide important feedback to the project. This way ITER will know ahead of time how the behaviour of its components will change during years of experiments, which will inform maintenance schedules.

Part of the EUROfusion Roadmap

This research addresses just one of the many scientific and technical challenges of fusion. EUROfusion is driven to provide solutions to all these in order to realise commercially-viable, low-carbon, plentiful and safe fusion power as soon as possible this century. Our programme addresses this particular topic in Mission 3 – Neutron Resistant Materials of the European Research Roadmap to the Realisation of Fusion Energy.