In fusion machines, plasma interactions with the walls, as well as maintenance phases, can produce micro-debris or dust in the vacuum chamber (dust is defined as particulate matter up to ~1mm in size).

In ITER, most of the dust produced will be made of tungsten, a heavy element used as a material for its plasma components. During experiments, this dust can be mobilized, transported into the plasma core and become a source of pollution, degrading plasma performance and potentially leading to its extinction. They also represent a safety issue in the event of accidental release into the environment, as they will be radiotoxic. In order to minimize these risks, the dust inventory in ITER is strictly limited. In order to achieve this objective, it is essential to understand the dust creation phenomenon under conditions as close as possible to ITER.

It is in this context that CEA (Institut de Recherche sur la Fusion Magnétique IRFM), CNRS (Laboratoire de Physique des Interactions Ioniques et Moléculaires/PIIM and the Centre Pluridisciplinaire de Microscopie Électronique et de Microanalyse/CP2M at Aix-Marseille University), and IRSN have been working for several years on research into the physical and chemical behaviour of dust produced in tokamaks, and on the development of systems for measuring and recovering dust in the vacuum vessel.

Although much of this research is carried out in the laboratory and using numerical codes, the WEST tokamak, operated by CEA at the Cadarache site, is proving to be an indispensable tool for studying dust under conditions close to those of ITER. WEST’s plasma-facing components are also made of tungsten, either solid or with a coating just a few microns thick. This is particularly true of its divertor, the most thermally-loaded component in the machine, which incorporates components using the same tungsten monoblock technology as ITER.

Since 2017, samples have been taken from the divertor’s vacuum chamber after each experimental campaign (and before any human intervention) in order to understand the formation mechanisms. Two techniques are used to collect the dust: one using a “duster box”, a device designed and made available in collaboration with IRSN to collect the dust present [1] (figure 1), and the second using a suction technique, in collaboration with PIIM. The dust particles are then characterized by electron microscopy at CP2M to reveal their morphology and chemical composition, and thus determine their possible origins. An analysis is also carried out to estimate the quantity of dust created.

The results of these studies have recently been published [2] and show the presence of two distinct dust populations after the 2020 experimental campaign.

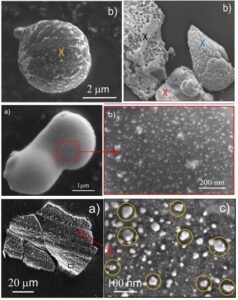

The first is dominated by particles ranging in size from a few microns to a few tens of microns, generally containing tungsten, but also boron, carbon and oxygen. These dust particless come from the delamination of tungsten coatings, the emission of molten material droplets following intense thermal loading, or formation due to plasma erosion of materials. Moreover, nanocavities were found on the surface of tungsten dust collected after a phase of WEST operation with helium plasmas. This can be attributed to the trapping of helium in tungsten in the form of nanobubbles, a phenomenon identified in the laboratory and found again under tokamak conditions.

The second population of dust highlighted in this study is more surprising: it concerns tungsten nanoparticles (figure 2). They were found mainly on the surface of particles of a few µm and can result either from the condensation of a supersaturated vapor above molten tungsten, or from ion-neutral clusters developing in plasma regions at low temperatures until the appearance of solid particles.

This characterization work was conducted following the dust collections carried out during the first WEST experimental campaigns (phase I) but it is ongoingduring the second phase.

A major change in the divertor components was made between these two phases of operation, involving the replacement of all its uncooled, tungsten-coated graphite components with water-cooled solid tungsten components using ITER technology (figure3).

The impact of these changes will be studied on dust production and behaviour.

Références:

[1] S. Peillon et al., Nuclear Materials and Energy 24 (2020) 100781

[2] C. Arnas et al., Nuclear Materials and Energy 36 (2023) 101471