Inside the ITER tokamak, there will be many diagnostic devices that will be the “eyes and ears” of the machine. They will inform experts on the relevant parameters of the plasma to control the fusion reaction. As it takes place, neutrons of 2.5 MeV and 14 MeV will be produced in the vacuum vessel. The Radial Neutron Camera (RNC) will detect them and assess the performance of the reaction – the more neutrons, the more successful.

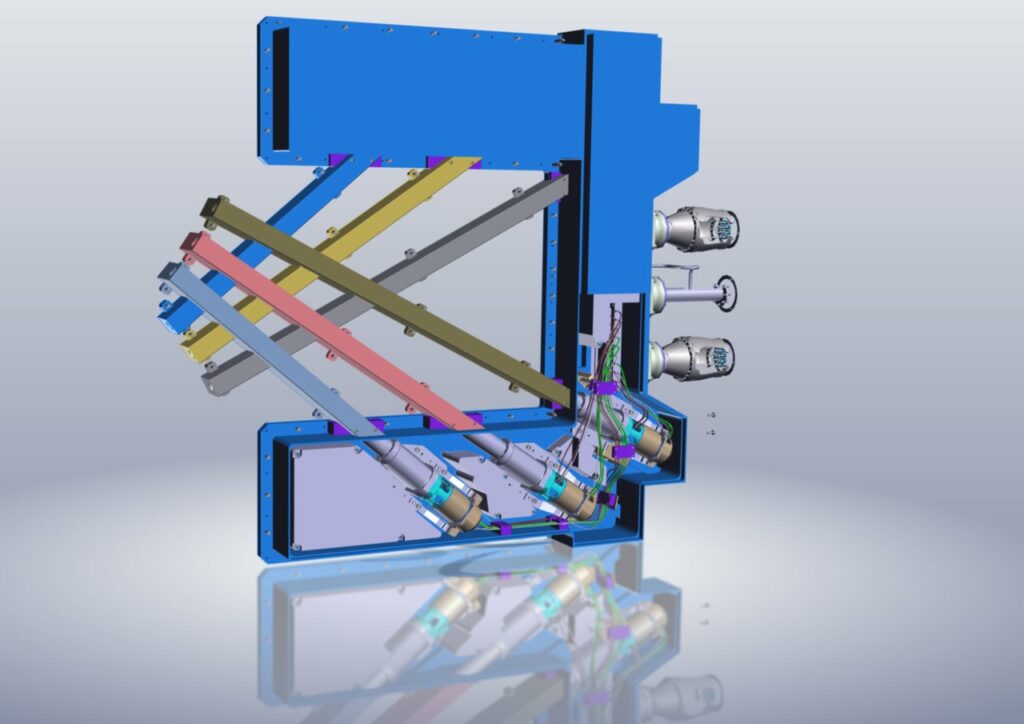

The RNC will be located in ITER Equatorial Port 1, subjected to the harsh conditions in the machine – high temperature and, needless to say, high neutron fluxes. It will be made of ex-vessel components to look at the core of the plasma, and port-plug components that will point towards the top and bottom parts of the plasma. The structure is the same for both ex-vessel and port-plug sub-systems: collimators will collect the neutrons and carry them towards the detectors. F4E is about to finish the design of the port-plug part, and to move forward with manufacturing.

This final design is the result of a collaboration with several European fusion laboratories. The RNC Consortium, led by ENEA (Italy), includes IST (Portugal), IFJ PAN and IPPLM (both from Poland). The team prepared a preliminary design of the port-plug RNC in March 2020 based on two detectors, placed one after the other, so that neutrons coming from the plasma can be detected either in the first or the second one. In fact, most neutrons will just go through the whole system unnoticed. However, some of them will hit the uranium layers used in the high purity uranium-238 fission chamber – the first detector. Others will avoid that but will collide with carbon atoms in the chemical vapour deposition (CVD) diamond neutron detector. The former is a proven and robust detection technology but lacks the capability to detect 2.5 and 14 MeV neutrons alone. By contrast, the CVD diamond detector can detect them but it is less robust.

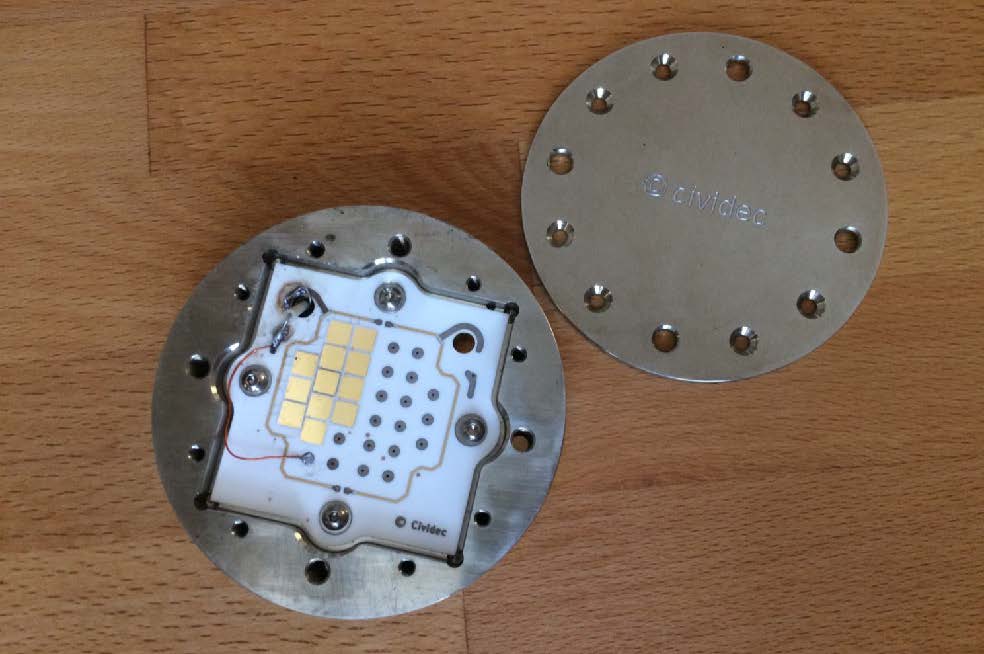

At first, designers thought of including an in-vessel water cooling loop to protect the CVD diamond detector from high temperatures. However, the strict ITER requirements posed new challenges to integrate this new piece of equipment. Benoit Brichard, F4E Diagnostics, explains how they found a solution. “F4E engaged in an R&D effort to develop a high-temperature resistant CVD diamond detector. This resulted in the delivery of a successful prototype by CIVIDEC Instrumentation, an Austrian contractor. The RNC Consortium tested the prototype, which successfully underwent a two-month thermal baking cycling. I am very pleased to say that we have been able to drastically simplify the design, ease the ITER operation and above all eliminate a safety risk.”

While the last details of the design are being addressed, engineers are preparing the manufacturing phase in parallel. A tender will be launched towards September 2022 for the fabrication of the port-plug RNC, which is expected to be completed in 2025.