One of the central goals of this EUROfusion Engage Newsletter is to demystify some of the complex challenges in the field of nuclear fusion for those who are not familiar with the field. Imagine research progress as putting together a puzzle: it starts with a scattered collection of pieces – pieces of information that initially seem overwhelming. Gradually, as one piece connects with another, a clearer image begins to emerge. At first, progress may seem slow, similar to the painstaking first steps of putting together the edges of the puzzle. However, as time unfolds and insights deepen, distinct patterns emerge, strategies solidify, and the path ahead becomes ever more refined and impactful. This week’s feature provides an exemplary snapshot of how we’re piecing together the puzzle of transforming small lab experiments into tangible products for future reactors, like DEMO and beyond. It highlights the journey from the base material – in this case coated tungsten textile fabrics – to the final product: a tungsten fiber-reinforced composite. This composite has been integrated into the design of components intended for use in ITER, serving as a potentially superior alternative to pure tungsten. As we’ve discussed in previous posts, long-term operation of nuclear fusion reactors demands materials that last. Upscaling and testing these potential solutions require resources and time. Once these challenges are fully understood and optimised, they could evolve into a new piece of the puzzle and become part of the bigger picture.

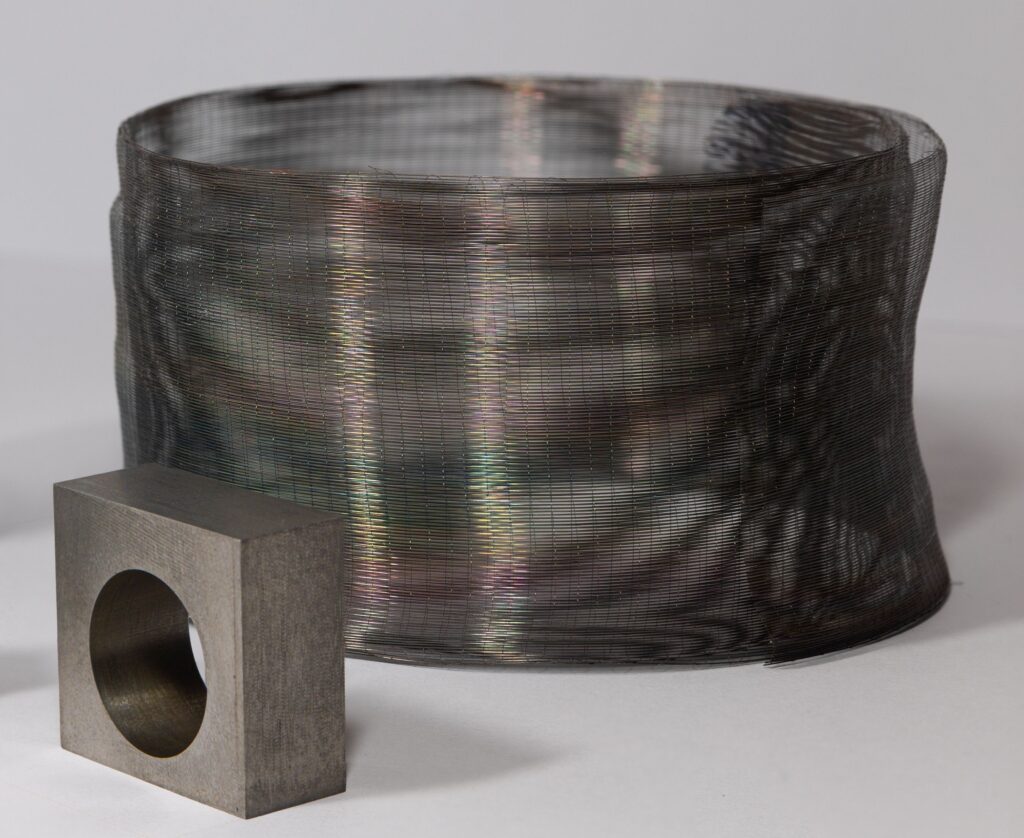

“This picture shows a tungsten fiber-reinforced composite produced via powder metallurgy techniques. For several years, the introduction of long fibers seemed very difficult and even almost impossible. The progress that has been made in recent years is remarkable. There is ongoing exploration into ways to further enhance these materials, aiming to improve both their manufacturing processes and performance characteristics, and one day these production methods and products could be used for various applications. Overall, I am convinced that R&D in extreme applications such as nuclear fusion holds immense promise for discovering solutions applicable in various other fields.”

– Alexander Lau

Find Alexander Lau on LinkedIn and X: @LauAlexander164.